Lightweight Fill and Stone Columns

…with Eccentric Loading in the Presence of Organic and Clay Soils

Introduction

The designed building is significant in the plan, a 7-story building with dimensions of 50 m x 80 m.

- The main difficulties of the project were the following factors:

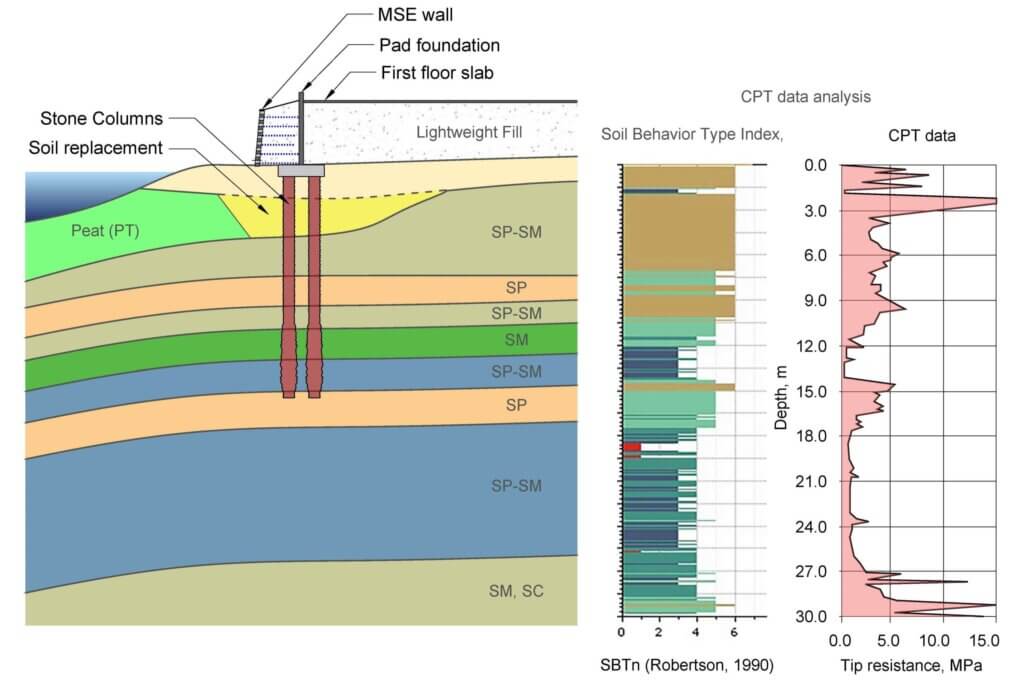

The building is located on a site with uneven relief with a difference in the height of about 4 m. In order to form a single level, a retaining wall is required, for this purpose, it was planned to use of an MSE (Mechanically stabilized earth) wall - The construction site was adjacent to the existing lake, and the retaining wall side identified the presence of organic soils at a depth of 2 to 4 m, up to 2.5 m thick

- The building foundation and the MSE wall were built in parallel. The absence of a backfill on the MSE wall side and a significant backfill, up to 4 m, on the other side caused horizontal movement of the foundation, which caused problems during subsequent construction.

In accordance with the recommendations of the geotechnical report (made by others), the following options were considered by the customer as foundation solutions:

- Stone Columns

- Pile foundations: 400-500mm diameter augercast piles extended 27-30m below existing grades.

Solution:

Soilmechanics studied in detail the geotechnical report, loads, and structural features of the building, as well as performed 3D calculations in the Plaxis 3D software.

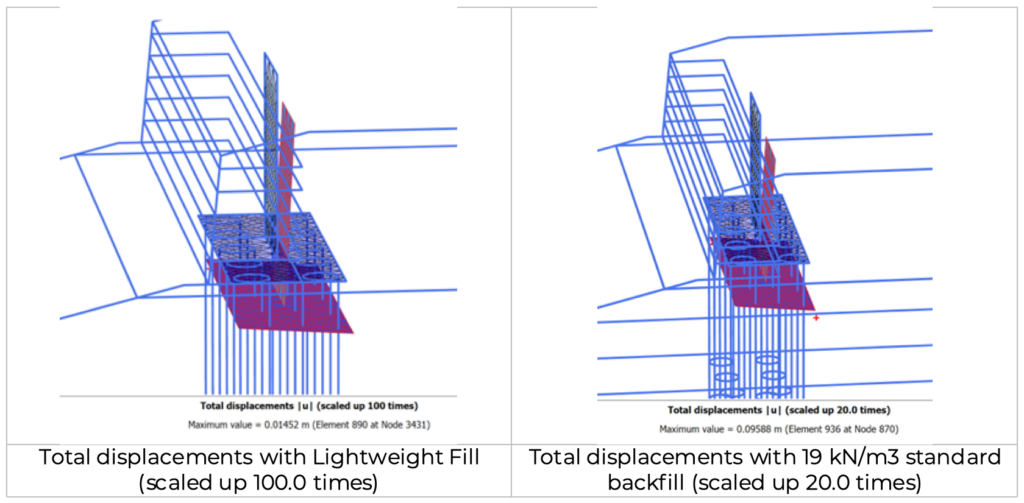

According to the results of the calculations, even with the replacement of organic soils under the MSE wall, the horizontal displacement of the foundation exceeded the allowable limits. It was also obtained that without additional measures to improve the soil: piles, or stone columns, the stability coefficient of the MSE wall is less than required.

The customer did not want to consider Pile foundations because of the significant horizontal forces on the piles, the effect of negative friction, and the extremely high cost.

Soilmechanics needed an innovative solution.

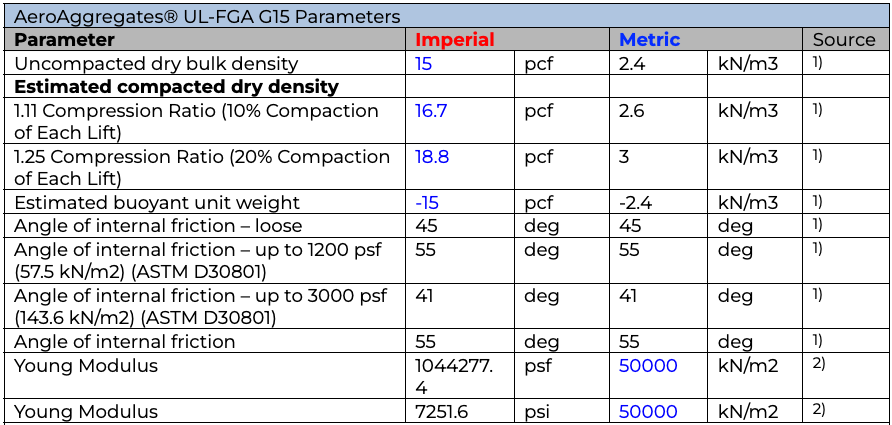

To reduce the horizontal pressure on the foundation and MSE wall, we proposed using Lightweight Fill material (Foamed Glass Aggregate), with the parameters shown in the table below.

Table 1. Lightweight Fill material parameters

Notes:

1) AeroAggregates® Technical Data brochure,

2) FOAMED GLASS AGGREGATE: A LIGHTWEIGHT FILL ALTERNATIVE FINDS THE U.S. MARKET Theresa Andrejack Loux, Ph.D., P.E., AeroAggregates LLC, Eddystone, PA, USA Harry E. Laspee, P.E., Pennoni, Philadelphia, PA, USA Archie Filshill, Ph.D., AeroAggregates LLC, Eddystone, PA, USA

As it can be seen in the table, the Lightweight Fill material’s unit weight in a compacted state is about 2.5 kN/m3, which is about 8 times less than the traditional backfill material with a unit weight of 19-21 kN/m3.

In our proposed solution, the stone columns were used only under the foundation, and not under the entire area of the backfill, which allowed us to optimize the economic aspect of the project.

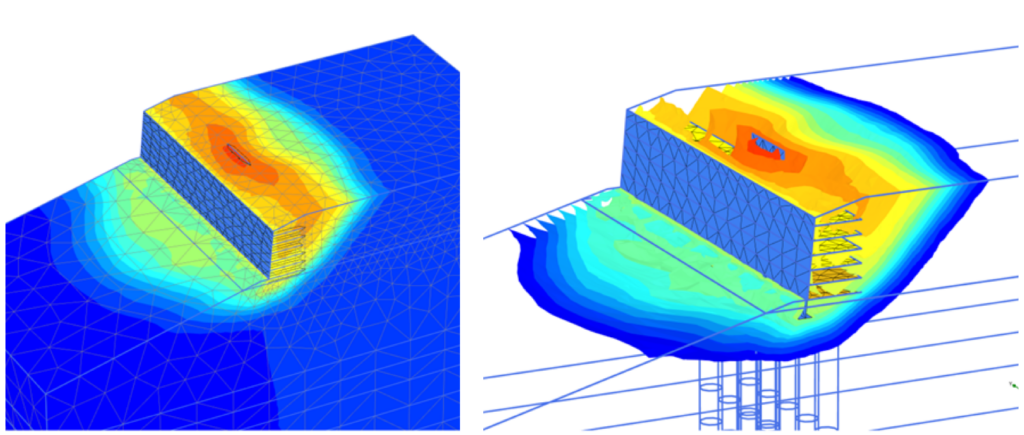

According to the results of the calculations, the solution described above fully met the customer’s requirements, both in terms of maximum horizontal displacement of the foundation and in terms of overall stability.

Figure 1 shows a sketch of the design solution developed by Soilmechanics.

Figures 2 and 3 below show results of a comparison of obtained settlements of the foundation for options with standard backfill and light backfill as well as results of calculation of overall stability taking into account the stone columns and MSE wall.

Facts

The cost of Ligthfill Aggregates can be slightly more expensive than sand for backfill, however, by significantly reducing the load on the soil from the backfill, using Ligthfill and stone columns allowed to eliminate the pile option and save the customer a significant amount of money and time for construction.